When businesses talk about accounts payable (AP) optimization, they often focus on the obvious: faster invoice approvals, streamlined payment runs, and better supplier relationships. But there’s a silent efficiency killer hiding in plain sight — supplier matching.

If AP automation is the engine of efficiency, supplier matching is the alignment of the wheels. Without it, the ride is bumpy, wasteful, and prone to costly errors.

What Is Supplier Matching — and Why Does It Matter?

Supplier matching is the process of verifying that supplier-related data — invoices, statements, purchase orders, and payment records — align perfectly before a payment is approved.

In practice, it means checking:

- Supplier names and codes are accurate across systems

- Invoices match the correct supplier accounts

- Purchase order (PO) references align with the right vendor

- Payments are recorded against the correct supplier balance

When this step is skipped or poorly executed, errors ripple through your entire AP cycle. The result? Duplicate payments, reconciliation headaches, damaged supplier trust, and wasted time on avoidable disputes.

The Hidden Costs of Skipping Supplier Matching

Many AP teams treat supplier matching as a low-priority, “we’ll catch it later” task. But that mindset costs more than you think.

| Without Proper Supplier Matching | With Supplier Matching |

|---|---|

| Duplicate or incorrect payments | Payments tied to correct supplier accounts |

| Discrepancies discovered during audits — when it’s too late | Discrepancies caught before payment |

| Increased supplier disputes and strained relationships | Fewer disputes, stronger partnerships |

| Delayed month-end closing due to reconciliation chaos | Faster, cleaner closing process |

| Wasted AP staff hours fixing preventable errors | More time for strategic tasks |

The Role of Supplier Matching in AP Optimization

Accounts payable optimization isn’t just about speed — it’s about accuracy and control.

Skipping supplier matching is like running a marathon in untied shoes. You might still cross the finish line, but you’ll waste energy, slow yourself down, and risk tripping along the way.

Three core reasons supplier matching is central to AP success:

- Accuracy Before Automation

Even the most advanced AP automation tools can’t fix messy supplier data. Matching ensures the foundation is clean before automation speeds things up. - Compliance & Audit Readiness

Supplier matching creates a clear, traceable link between payments, invoices, and suppliers — a must for passing audits without panic. - Supplier Relationship Management

Correct, timely payments build trust. Mistakes, on the other hand, erode credibility and make suppliers less cooperative when you need flexibility.

Supplier Matching vs. Supplier Invoice Matching

It’s easy to confuse supplier matching with supplier invoice matching — but they’re not the same.

- Supplier Matching: Ensuring all transactions, records, and payments are linked to the right supplier in your system.

- Supplier Invoice Matching: Verifying that an invoice matches purchase orders and receiving records.

Think of supplier matching as identity verification and supplier invoice matching as transaction verification. Both are critical — but supplier matching comes first, ensuring the rest of your AP process isn’t built on bad data.

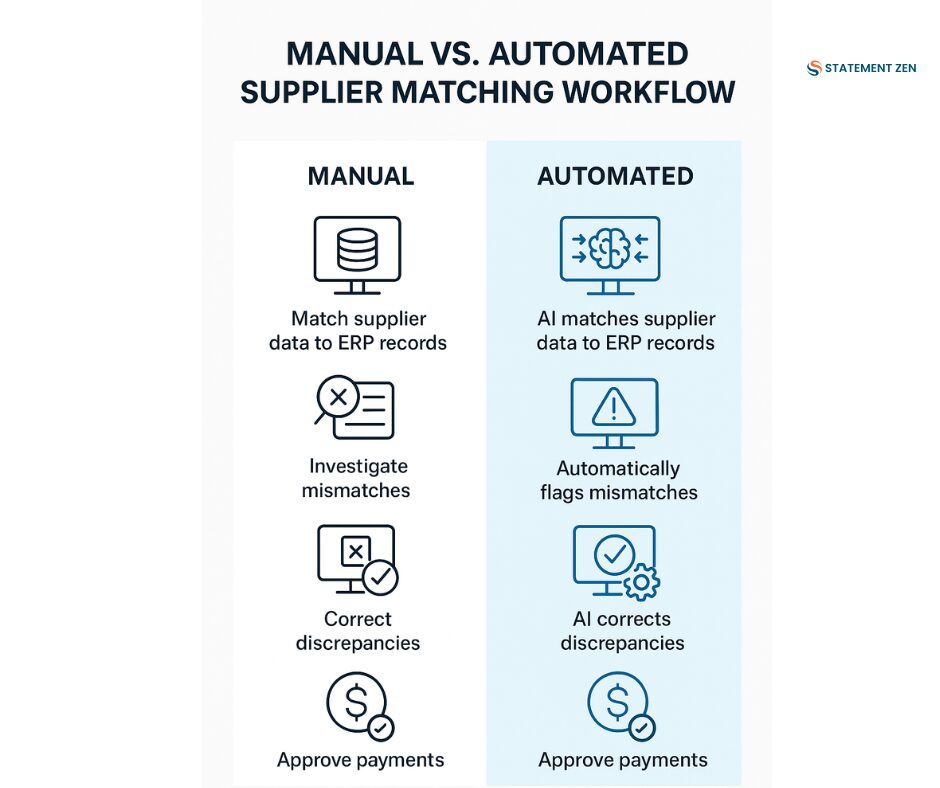

The Supplier Matching Workflow in AP Automation

When done right, supplier matching becomes a frictionless part of your AP process — not an extra chore.

Here’s how it works inside a modern supplier matching insights solution:

- Data Extraction

Supplier details are pulled from invoices, statements, and POs using OCR and AI. - Data Normalization

Different naming conventions (“ABC Ltd.” vs. “ABC Limited”) are standardized. - System Matching

Supplier records are matched to ERP or AP system entries using unique identifiers. - Exception Flagging

Mismatches trigger alerts for manual review. - Automated Resolution

AI learns common matching patterns and resolves recurring issues without human intervention.

Common Supplier Matching Challenges

Even with automation, supplier matching isn’t always straightforward. Common roadblocks include:

- Multiple Supplier Accounts for the same vendor in your system

- Inconsistent Naming across invoices, POs, and contracts

- Merged or Acquired Vendors that lead to outdated account details

- Poorly Maintained Master Data with duplicate or inactive suppliers

- Manual Data Entry Errors that automation inherits without verification

Solving these challenges requires a mix of automation technology and AP discipline.

Best Practices for Effective Supplier Matching

Here’s a proven playbook for optimizing supplier matching in your AP process:

- Start with Clean Master Data

Review and clean your supplier master list quarterly to remove duplicates and inactive records. - Use Unique Identifiers

Always match based on supplier codes or tax IDs, not just names. - Standardize Naming Conventions

Adopt a consistent format for supplier names across all systems. - Leverage AI & Automation

Use reconciliation software to identify and correct mismatches faster. - Integrate Supplier Matching into AP Workflows

Make it a default part of invoice processing, not a separate “cleanup” task. - Train Your AP Team

Ensure staff understand the importance of supplier matching and how to resolve exceptions.

How Automation Elevates Supplier Matching

Modern AP teams don’t just match suppliers manually — they deploy supplier matching expertise tools that integrate AI and analytics to detect discrepancies instantly.

Key benefits include:

- Speed — Match supplier data in seconds, not hours

- Accuracy — AI reduces human error in matching

- Scalability — Handle thousands of supplier records without bottlenecks

- Proactive Alerts — Identify and fix mismatches before they delay payments

- Audit Trail — Maintain a full record of matches and corrections for compliance

Case Example: Cutting Supplier Disputes by 75%

One global manufacturing firm integrated automated supplier matching into its AP workflow. Before automation, supplier mismatches were causing over 200 disputes per quarter. Six months post-implementation:

- Disputes dropped by 75%

- Month-end close was completed 3 days faster

- AP staff reallocated 30% of their time from corrections to strategic supplier analysis

FAQs on Supplier Matching

1. Is supplier matching only important for large businesses?

No — even small AP teams benefit. The fewer invoices you process, the more damaging each error becomes.

2. Can’t my ERP handle supplier matching automatically?

Most ERPs have basic matching, but dedicated tools offer AI-driven precision and cross-system integration.

3. How often should we review supplier matching accuracy?

At minimum, quarterly. But with automation, accuracy checks can run continuously in the background.

The Bottom Line

Supplier matching is not a nice-to-have. It’s the silent guardrail keeping your AP process aligned, accurate, and efficient. Without it, optimization efforts are like pouring premium fuel into a car with misaligned wheels — you’ll burn resources without getting full performance.

The good news? With AI-powered supplier matching, you can integrate this essential step seamlessly into your AP workflow, reducing disputes, accelerating closing cycles, and building stronger supplier relationships.

Next Step: See how Statement Zen’s supplier matching insights can help you eliminate errors before they happen and build an AP process that scales with your business.