Avoid costly reconciliation mistakes. Learn the 5 most common statement matching errors, why they happen, and how to prevent missing invoices, unapplied credits, and supplier matching issues.

Even the best accounts payable (AP) teams make mistakes — but in statement matching, a small oversight can mean the difference between accurate books and a financial mess. From missing invoices to supplier matching issues, errors in the matching process slow down payments, frustrate suppliers, and damage your audit readiness. This guide breaks down the five most common statement matching errors, explains why they happen, and — most importantly — shows you exactly how to avoid them.

So let’s be blunt: the five things below are the recurring reasons finance teams lose money and credibility. Know them. Fix them. Move on.

1. Missing invoices — the silent cash leak

A missing invoice shows up on a supplier’s statement but never made it into your AP system. That’s the classic “we didn’t see it” problem — not because someone is incompetent, but because your intake process is porous.

Why this happens: invoices get emailed to the wrong inbox or person, they get routed through purchasing instead of AP, they get lost in spam, or they arrive as paper and sit on someone’s desk. When there’s no single point of entry, that paper trail becomes a Bermuda Triangle.

The real cost: missed early‑payment discounts, last‑minute panic payments at vendor rates, strained supplier trust, and hours of detective work tracing a single invoice. One “miss” often escalates into several manual transactions and a dispute that takes days to resolve.

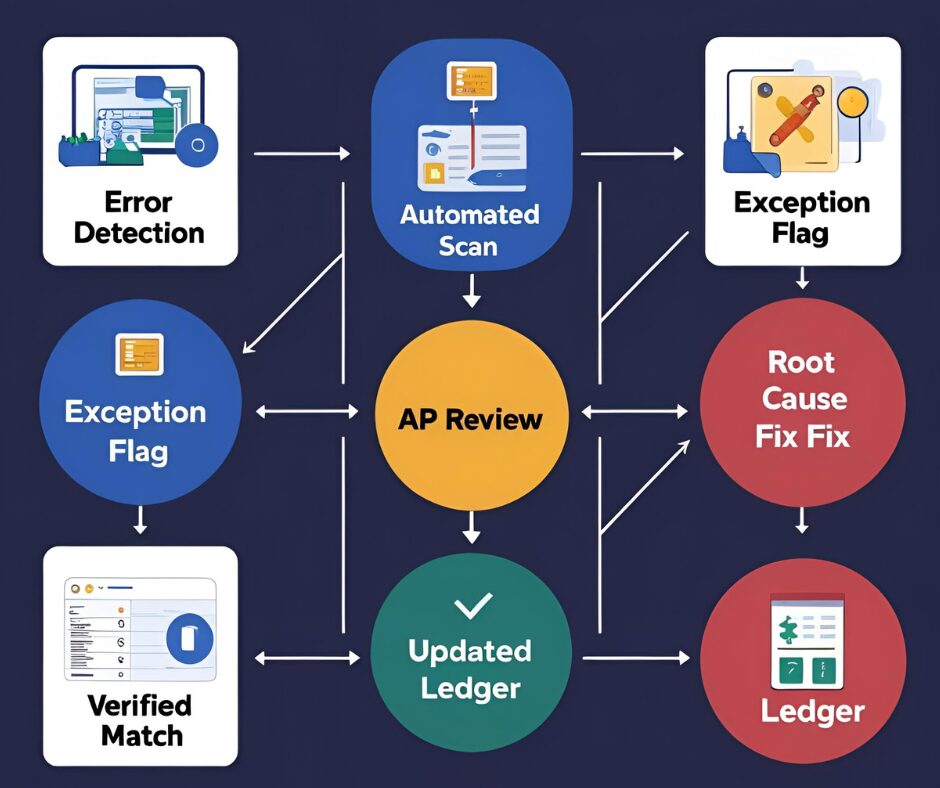

Fix it now: create one, auditable intake channel for every invoice (a single email alias + a portal). Make sure every incoming document is timestamped and logged. If you’re ready to stop the reactive scramble altogether, consider automated statement matching to capture and log invoices the moment they arrive — no human finger required.

2. Duplicate payments — expensive and embarrassingly avoidable

Duplicate payments happen when the same invoice is entered more than once — maybe under a slightly different reference number, or because the vendor resent the invoice without marking it “copy.” Weak internal controls and poor communication compound the risk.

Why this happens: a clerk re-enters an invoice because they can’t find it, or two different AP staffers process the same invoice in parallel. Sometimes suppliers resend invoices, and the system doesn’t flag the duplicate.

The real cost: immediate cash leakage and the administrative nightmare of chasing refunds. Recovering duplicate payments is slow and can cost more than the payment itself when bank fees and reconciliation time are included.

Fix it now: your system must lock processed invoices, require PO + invoice number match before payment, and flag near‑matches (amount + date + vendor) automatically. A statement matching engine that proactively identifies probable duplicates saves you the embarrassment and the money.

3. Incorrect amounts — small data errors, big consequences

When what’s recorded in your AP ledger doesn’t equal what appears on the supplier statement, the problem can be as trivial as a misplaced decimal or as structural as tax/discount rules being applied inconsistently.

Why this happens: manual keying errors, the wrong tax code, a discount not applied, or price changes that were never recorded in the PO system. Occasionally, a supplier invoices based on a new rate and forgets to notify you.

The real cost: overpayments, underpayments, disputes, and the time spent untangling who’s right. Even one persistent mismatch can delay payments, activating penalty clauses or souring relationships.

Fix it now: automate the data extraction step to remove human typos, route exceptions into an exception workflow for investigation, and make price‑change verification a mandatory pre‑payment step — procurement confirms any rate changes before AP issues payment.

4. Unapplied supplier credits — hidden working capital sitting on the table

Supplier credits that never get applied look harmless on a statement but they inflate your liabilities and bleed working capital. The supplier thinks you owe less than you do, you think you owe more — you both lose.

Why this happens: the credit gets sent to the wrong person, it’s not linked to the original invoice, or there’s simply no follow‑up process to apply small credits. Credits sometimes land in a separate inbox and then get ignored.

The real cost: overstated payables, less usable cash, and missed opportunities to offset payments. Over time, unapplied credits distort vendor performance reports and hide negotiating leverage.

Fix it now: require suppliers to list open credits on every statement, log credits immediately into AP when received, and make credit application a standard step in monthly reconciliation. Your statement audit procedure should include explicit credit checks — part of a repeatable checklist. (link: Features — “statement audit tools”)

5. Outdated or inconsistent data — timing, not errors

Sometimes both sides are right: your AP ledger shows payments processed on a different cut‑off date than the supplier’s statement, or a payment was in transit when the statement was issued. Those are not mistakes — they’re timing differences that look like discrepancies.

Why this happens: different cut‑off dates, bank transit times, or delayed supplier updates. Large suppliers may batch statements weekly or monthly, while you run daily or real‑time ledgers.

The real cost: wasted time chasing non‑issues, false-positive exception reports, and frustration that dilutes trust in your reconciliation process.

Fix it now: proactively agree on cut‑off dates with key suppliers, flag suspected timing differences rather than treating them as errors, and introduce a short‑term “pending” category that holds items until bank clears. Communicate payment schedules and cut‑off rules transparently — most timing conflicts evaporate when both sides are aligned.

Case Study: Cutting Matching Errors by 90%

A national retail chain ran monthly matches manually, taking 5–6 days per cycle. Common issues: missing invoices and unapplied credits.

After moving to automation:

- Missing invoices dropped 93%

- Duplicate payments eliminated within 4 months

- Matching cycle time reduced from 6 days to 7 hours

Frequently Asked Questions

Q1: What’s the most common statement matching error?

Missing invoices — especially in high-volume AP teams still using manual processes.

Q2: Can automation completely prevent matching errors?

It can remove 80–90% of manual-entry and duplicate errors, but exceptions still require human judgment.

Q3: How often should error checks be run?

At least monthly, but high-volume suppliers should be reviewed weekly.

Q4: Does automation improve audit readiness?

Yes — automated systems create a complete audit trail of every match and resolution.